TIG Welding Torch provides the ultimate solution for hard-to-reach applications. The body can be bent to virtually any position, allowing quick and easy access to the most difficult positional welds.

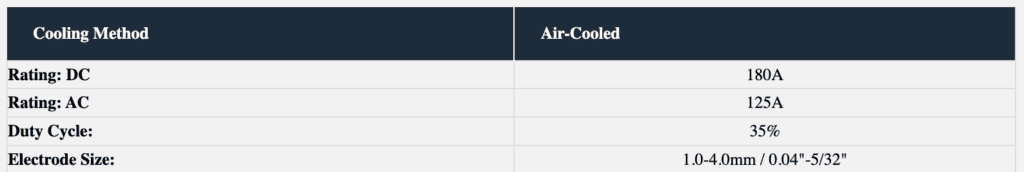

Air-Cooled High-Performance

TIG Welding Torch provides the ultimate solution for hard-to-reach applications. The body can be bent to virtually any position, allowing quick and easy access to the most difficult positional welds.

Gas Stream Cooling

Force Cooling Technology A highly effective series of passages and wells force cools the collet. The cooler running collet assembly maximizes conductivity and extends consumable life.

Heat Zone Isolation Technology

Transferred heat from the ceramic cup is isolated by a unique external barrier. Conducted heat is isolated using large air pockets within the torch body structure resulting in cooler running torches with increased power to weight performance ratios.

Wear Parts

Every component delivers superior performance for increased Arc time and lower overall production costs

Torch Bodies and Back Caps

Step change performance levels achieved with the development of revolutionary cooling and heat zone isolation techniques

Key Benefits

Cable Systems

Clever material selection combines flexibility, durability, and performance.

Key Benefits